This story was produced by Grist and co-published with The Guardian.

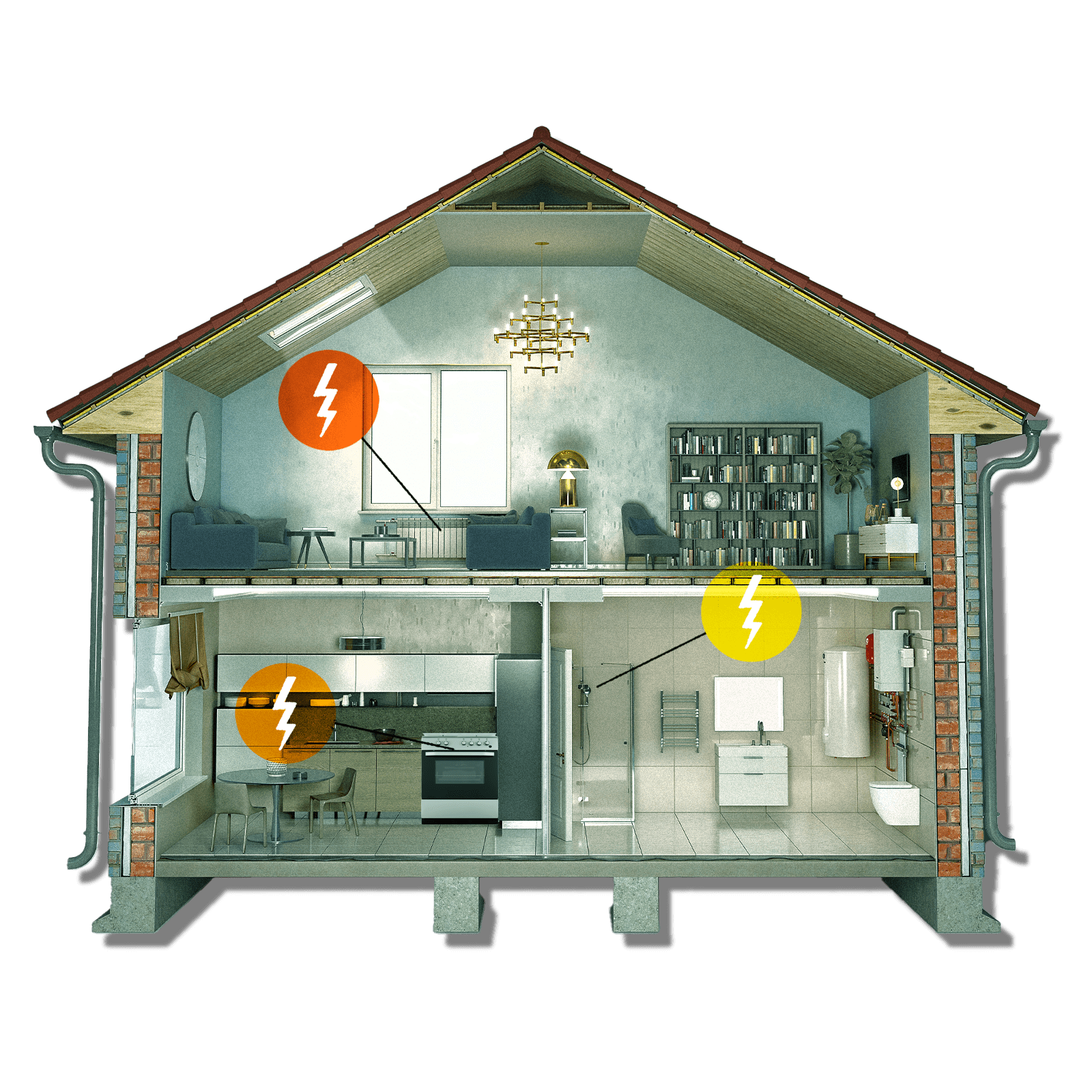

My wife and I live in a green, two-story colonial at the end of a cul-de-sac in Burlington, Vermont. Each spring, the front of our home is lined with lilacs, crocuses, and peonies. The backyard is thick with towering black locust trees. We occasionally spot a fox from our office windows, or toddlers from the neighborhood daycare trundling through the woods. It’s an alarmingly idyllic home, with one exception: It runs on natural gas.

The boiler, which heats our house and our water, burns it. So do the stove and the dryer and even the fireplace in the living room. Some 60 percent of American residences are similarly reliant on gas, the primary component of which is the potent greenhouse gas methane. This dependence on fossil fuels didn’t particularly faze us in the past. When we had to replace the furnace in our last place in late 2018, it was the easiest option. Same for the other appliances. At least it wasn’t oil, we told ourselves. It didn’t help that our contractors weren’t well-versed in alternatives and that our decisions were sometimes necessarily made in haste. When we did have time to explore switching to cleaner sources, the price tag often gave us pause. Can an induction stove really be that expensive?

Five years later, the landscape had shifted. The world was climbing dangerously toward 1.5 degrees Celsius (2.7 degrees Fahrenheit) of warming, and residential energy use accounted for one-sixth of all planet-heating emissions in the United States. We also wanted to start a family, and burning methane indoors can have potentially profound effects on human health. Then came the Inflation Reduction Act, which unleashed billions of federal dollars to help make cleaner technologies more ubiquitous and affordable than ever before. By early last year, we were ready to decarbonize.

I harbored no illusions that it would be the simple “five-step” process some advocates imply it is. But, as climate journalists, my wife and I figured a few weeks’ research and planning ought to get us most of the way there. What unfolded was more than a year of cascading decisions and obstacles that strained our wallets, tested our notions of comfort and sacrifice. While the late nights buried to my knuckles in spreadsheets calculating the payback periods on heat pumps and solar panels were, dare I say, fun, my nerves began to fray when the solar company we wanted to hire abruptly went out of business. They nearly broke when I saw what all of this would cost and shattered when I thought we’d have to upgrade the electrical panel. My wife found her limit when we were forced to choose between cutting emissions or cutting trees.

Frazzled and flustered, I sought help.

“I’m not surprised,” David Lis with Northeast Energy Efficiency Partnerships said of my predicament. Once people discover that going electric is an option, most run headlong into the complexities. “Your experience of having to navigate a lot of market actors is a big barrier.”

With each step, however, we became increasingly confident that decarbonization was possible. The question quickly became whether we were willing to bear the cost.

Every year, homes in the U.S. produce nearly 900 million metric tons of carbon dioxide. That’s about twice as much as all of France. One-third of those emissions are the result of directly burning natural gas and other fossil fuels onsite. The remainder comes from generating the electricity residences consume.

Our house is fairly typical. It was built in 1940, with three bedrooms, two bathrooms, and 1,672 square feet of living space. We combust about 65,000 cubic feet of gas each year keeping warm, cooking meals, and doing laundry, or about the norm in the Northeast. Going electric would shift those emissions to the cleanest grid in the country; almost all of Vermont’s electricity comes from renewable sources. Those savings are why climate advocates often push people to “electrify everything.” But doing that can, as we found out, become comically complicated.

“It’s definitely important to have a plan going in,” said Cora Wyent, director of research for the electrification nonprofit Rewiring America, which recently released a personal electrification planner to help people plot their path to decarbonization. I reached Wyent about halfway through ours and wished I had found her sooner. Making a roadmap, she said, helps folks maximize incentives from the Inflation Reduction Act, or IRA, some of which can be redeemed multiple times because they reset annually. It also can help avoid unexpected, and often costly, electrical work to ensure your house can supply the needed power, said Wyent. “Making a plan can also help you stay within the limits of your electric panel.”

As for what to prioritize, she says that depends on your motivation. If your goal is minimizing greenhouse gas emissions, for example, ditching fossil fuel heating would likely have the largest impact. Those concerned about indoor air quality might prefer to start with appliances (particularly stoves). If in doubt, electrifying whenever something breaks is often the simplest pathway to a lower-carbon home.

“When it dies, electrify,” quipped Wyent. That approach means paying only for things that need replacing anyway, and can split the unwieldy into smaller, more manageable projects. It’s where we decided to start early last year when our water heater was aging to the point of hazard. Then we’d turn to the stove and our heating system, in no particular order. The dryer was less urgent, but needed to go for us to disconnect the gas line. We also knew we wanted to get as much work done as possible while we were making other renovations, especially because we now had a baby on the way. We were in the fortunate position of having enough cash from the sale of our previous home that financing wasn’t an immediate barrier, so long as we decided an investment was worth it.

Our first foray into discarding gas was installing a heat pump water heater. It works a bit like an air conditioner in reverse by drawing warmth from the surrounding air to bring water up to temperature, and the technology is growing in popularity. Not only are heat pumps energy-efficient, they also can do a bit of dehumidification, which our musty basement sorely needed. The process went deceptively smoothly.

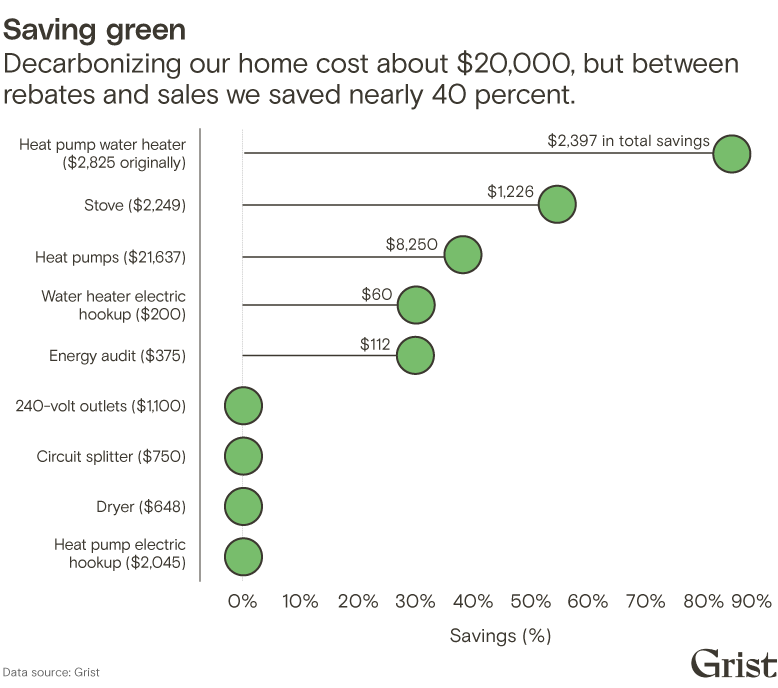

We gathered several quotes — something Wyent and others told me is critical to managing costs. The lowest was $2,825 to install a 50-gallon tank, a price that was on the high end of Energy Star guidance but hundreds less than the others. A $600 instant rebate from the state and an $800 post-purchase one from the city brought the figure to $1,425. I happened to have a friend who needed one too, so we both got another $150 off for doing them together. The IRA provides a tax credit of 30 percent of the total cost (up to $2,000), though we won’t get it until after we file our taxes.

All told, the bill will come to $428, plus a couple hundred more to have an electrician wire it. Installation took less than a day and the water heater is now humming happily in our basement. Although the emissions savings will be negligible because we still need our boiler for space heating, it was a confident first stride toward reducing our dependence on gas.

Buoyed by the success, we took aim at the stove and the dryer.

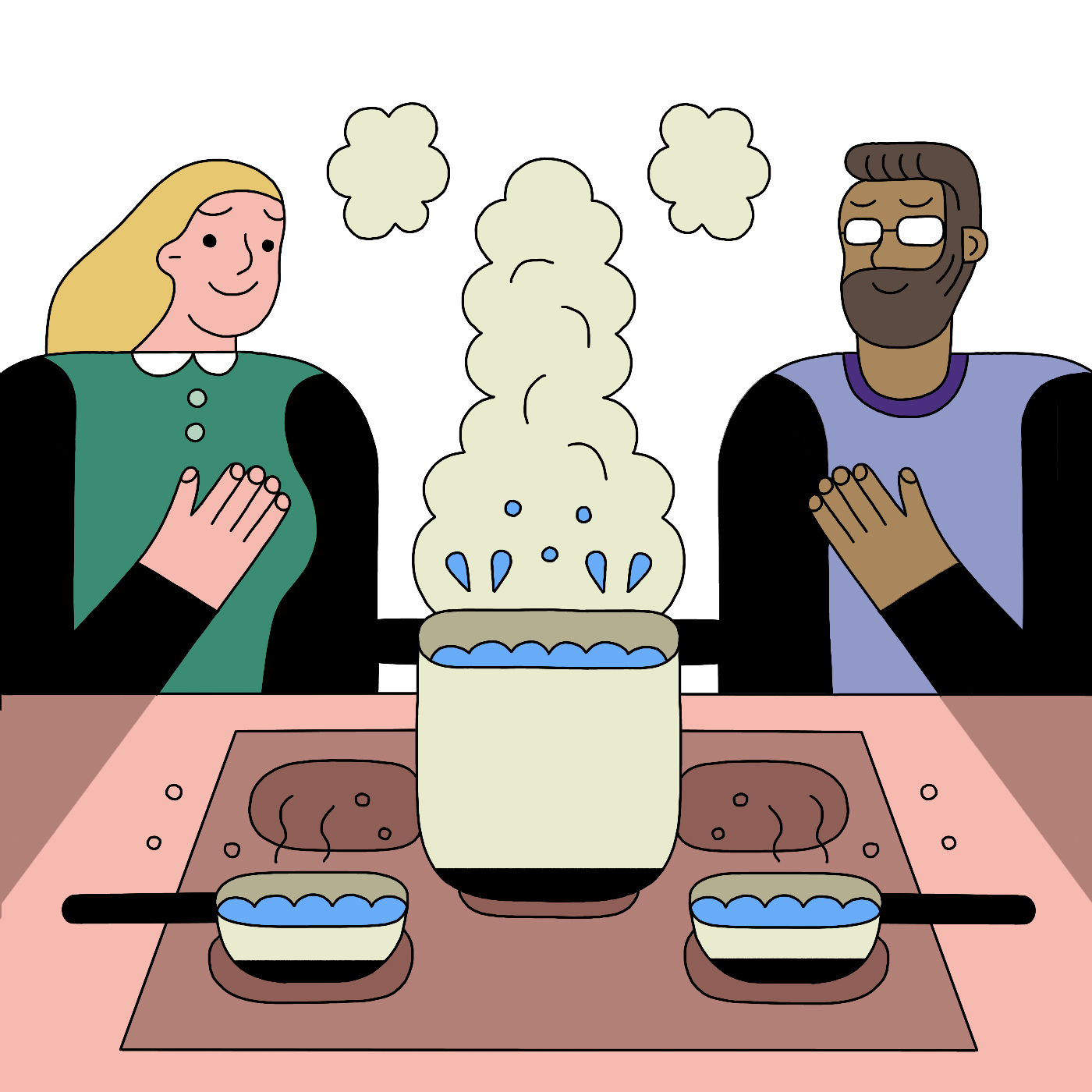

Electrifying appliances isn’t yet a major climate win. The average dryer uses around 2,000 cubic feet of natural gas a year, with CO2 emissions roughly equivalent to driving about 300 miles. Gas stoves consume about the same amount. At best, going electric fully displaces those greenhouse gases. But the advantages are even smaller beyond Vermont, where local utilities aren’t as clean. The nation still generates 60 percent of its electricity with fossil fuels (43 percent of that from natural gas) and until that changes, junking a gas stove is roughly a wash for the planet.

Our main motivation for jettisoning gas appliances was the blinking light on our air purifier. We’d read the research showing that cooking over gas produces benzene and nitrogen dioxide. But seeing that little diode change from a soft blue to a harsh red every time we cooked was a menacing reminder of the risks. It grew even more unsettling when we found out we’d become parents, as gas stoves have been linked to nearly 13 percent of the nation’s childhood asthma cases.

The consensus among climate experts and, perhaps equally importantly, chefs is that the best alternative is an induction stove, which uses electromagnetic energy to heat cookware. It requires less energy than a traditional electric range and offers greater temperature control. But as we started exploring options, we quickly realized the technology doesn’t come cheap. The least expensive models start at around $1,100, or almost twice the price of a basic gas stove. Advocates of the tech say prices should come down as it becomes more widespread, but that didn’t do us much good, and our city’s rebate was just $200. We hoped Black Friday would further blunt the financial blow, though that meant waiting a few months. We used the time to weigh whether we wanted features such as a convection oven (we did) and, come November, headed to Lowe’s.

Given my proclivity for buying power tools I don’t need, my wife hustled me directly to the appliances. Alas, the store had just one induction model on display, and it wasn’t the one we wanted. But the conventional stoves were similar enough that we could get a sense of how the induction version might feel in the kitchen. After much pressing, twisting, hemming, and hawing, we chose a Samsung induction model with knobs rather than buttons, which we knew from a relative’s experience could be finicky. The list price was $2,249, but we got it for nearly half off with the holiday sale.

On the way out, we solved our dryer dilemma when we happened upon a well-reviewed electric model similarly marked down to just $648. We pulled out our phones and compared it to a heat pump dryer, which would have used less electricity and spared us the trouble of installing another outlet and a vent. But aside from being considerably more expensive (even with an extra state rebate), the heat pump version had just half the capacity. Given the mountains of laundry newborns produce, we chose the traditional tech, with the hope that larger models are available next time we need a dryer.

Leaving the store, I nearly blew our savings on a track saw. Good job I showed restraint, as installing outlets to power our purchases was much more expensive than expected. The electrician charged more than $600 for the stove hookup, and the dryer outlet, when our basement revamp is ready to accommodate it, will likely run about the same. Although that’s about two-thirds the cost of appliances, we saw the benefits of ditching gas almost immediately.

My wife does most of the cooking and swoons when she switches on an induction burner. Water boils far faster than with the gas stove and even more quickly than in our electric kettle. “It feels almost instant,” she said. “The bubbles are crazy.” The heat is also precise enough to keep pasta sauce at a simmer and food perfectly warm while we gather our dinner plates.

Best of all, it’s been months since we’ve seen the red light on our air purifier.

With the relatively small stuff tackled, that left our biggest energy glutton: the heating system.

Heating and cooling account for more than half of a typical home’s energy use, according to Department of Energy data from 2020. Given that our gas meter hardly budges during our northern Vermont summers, it’s safe to assume the vast majority of our methane usage goes toward heating. That amounts to about 3.6 metric tons of planet-warming gases annually, or roughly what we’d spew driving 9,200 miles. That carbon footprint would largely disappear if we went electric.

We started with a home energy audit to ensure we didn’t have any major weatherization issues to fix. Sealing leaks, experts say, can be among the easiest and most cost-effective ways to reduce your energy bills and carbon footprint. The auditor deemed our house moderately porous — no surprise, given its age — but didn’t see anything obvious to plug. He said it wasn’t bad enough to warrant a big investment like new windows, but he did suggest insulating the basement, which we’ll get to eventually.

Our boiler, like other modern gas heating systems, converts around 90 percent the energy it uses to heat. That sounds great until you realize that heat pumps can be two to five times more efficient. This seeming feat of alchemy is possible because heat pumps transfer heat rather than create it — they push warmth into a building to bring the temperature up, or draw warmth out of to cool it. Heat pumps are also great for retrofitting a home because they can be used with or without ducts in the floors or walls.

They come in two basic flavors. To extract, or sink, heat, ground-source heat pumps rely on a network of tubing buried a few feet to a few hundred feet underground, where temperatures rarely fluctuate. Also known as geothermal, these systems circulate a mixture of water and antifreeze through the loop and back to the house. Air-source models instead utilize ambient air as their source.

Geothermal systems are more efficient, quieter, and last longer than their air-source counterparts. Because subterranean temperatures remain relatively constant, the weather also doesn’t affect how they operate. Although the buried piping can last 50 years or more (the components inside the house last about half that), installing it requires expensive drilling or digging. Contractors told us that outfitting the average home with geothermal can run $25,000 to $45,000 or more, even with government rebates and incentives.

“The higher upfront costs are the main reason I typically don’t talk to people about geothermal,” Wyent told me. But, if you can afford the initial financial hit and plan to be in your house long enough to reap a slower payback, they’re definitely worth considering. “The efficiency is fantastic.”

Compared to geothermal, air-source models use more power, have a lifespan of around 15 years, and lose some efficiency in very cold weather. But they generally run tens of thousands of dollars less — a factor that helps make them much more common, with sales outpacing gas boilers last year. It largely drove our decision as well. (Not that any of the geothermal installers I called were particularly convincing. A couple outright told me I shouldn’t do it.)

Because our house currently has baseboard heaters rather than ducts, we gravitated toward a “mini split” system. It consists of a condenser, installed outdoors, and an indoor unit called a “head,” with a thermostat and a fan that blows hot or cold air. The first contractor we spoke with suggested stationing two condensers outside and five heads throughout the house. He recommended systems designed specifically for colder climates,which are guaranteed to operate at temperatures well below zero.

That guy never followed up with a quote, though. The next bid came in at $25,950, which felt high. We gathered two more estimates, the lowest of which landed at $19,637. That included a few state rebates applied at the time of purchase; add in a $2,500 city rebate and the $2,000 IRA credit we’ll get at tax time, and the final cost will be about $15,000.

But there was a hitch: We heard that heat pumps could drive our electricity bills to untenable levels. Indeed, an estimate from Efficiency Vermont, the states’ energy efficiency utility, pegged the system’s consumption at 10,000 kilowatt-hours annually in heating alone. At our current rate of around $0.17 per kilowatt-hour, we’d spend $1,700 annually compared to the $1,100 or so we spend burning gas to keep warm.

That would make heat pumps too expensive to operate.

As we pondered how to make heat pumps affordable, the sun came to mind. It emits more than enough energy to power the world, and each gigawatt of power we harness from that star can avoid hundreds of thousands of tons of greenhouse gas emissions. The U.S. is increasingly tapping this essentially inexhaustible resource, with generation jumping from 5 gigawatts in 2011 to over 145 in 2022. According to the Solar Energy Industries Association, 7 percent of homes nationwide now sport photovoltaic panels. We hoped that becoming one of them could help lower our energy costs.

We asked our neighbors who installed their system, and a lovely salesman came by to prepare an estimate. Pointing to the peak of our roof, he noted that the ridge cap was getting wavy — a telltale sign that a new roof is in order. Given that the solar panels we would install are warrantied for 25 years, we’d want to take care of that now, because removing and replacing them down the line would be outrageously expensive. That sent me back to the phone to seek even more quotes, this time from roofers. The best of them came in at $10,000. Yet another project and expense, but an unavoidable one if we wanted solar.

By the time we sorted out the roof, the founders of the solar company had retired and shuttered the business. We had to negotiate with another installer called SunCommon and landed on a 26-panel system, with a capacity of 10,530 kilowatt-hours and a price of $31,765 before rebates. That’s slightly less than the average price per watt in our area and thousands less than the company’s initial estimate — another win for haggling.

Vermont doesn’t offer incentives for installing photovoltaic panels, but the IRA extended the 30 percent federal tax credit through 2032, bringing our eventual outlay to $22,236. The installer claimed we could lump the cost of the roof into that credit, but our accountant said IRS rules clearly exclude it. (The myth is persistent enough that everyone from solar companies to Reddit users are posting about it.) In any case, the next step for us was to have SunCommon verify that the satellite imagery it used to estimate the system’s output aligned with the realities of our roof.

A technician arrived on a dull gray morning in early December. After grabbing a few gadgets, tools, and a ladder from his truck, he spent the better part of two hours poking, prodding, and climbing on our house. Did we meet all the roof set back requirements? Are our rafters strong enough to support panels? How much shade is there? The answers to these questions and others could affect how much energy we could expect our array to generate.

The results would lead to one of the toughest decisions in our journey.

Black locusts start to leaf out each spring and become bushy caricatures of a tree within weeks. More than a dozen of these gorgeous giants horseshoe our backyard, providing a home to at least one owl, an assortment of songbirds, and, come winter, a roost for a murder of crows. At over 100 feet tall, they cast long shadows — not quite long enough to reach the front of the house, where 14 panels would soak up enough rays to return 83 percent efficiency. But the 12 panels at the rear would see only enough sunlight to perform at 55 percent of their potential, substantially lower than what SunCommon recommends to make an installation worthwhile.

With all that leafy cover, our system would be expected to produce just 6,900 kWh per year — much less than the company’s model predicted. Cutting down half a dozen or so trees would gain as much as 2,000 kWh a year, but come at a financial and climate expense, since trees are carbon sinks. Moreover, my wife would just as soon lose a limb of her own than needlessly fell a tree.

The black locusts would stay put. With that decision made, we finally had enough information to calculate what electrification would cost us — and whether it was worth it.

My spreadsheet, named HOME DECARBONIZATION in all caps, is a mere three tabs across. Two of them examine the merits of different size solar arrays — the entire roof, or only the sunnier front side — while the third is dedicated to the various heat pump configurations. Despite its meager size, it took hours to build. I’d find myself waking at all hours to fix an equation, adjust a parameter, or gaze into the grid hoping for answers. It was an affront to the hope that, as Lis at Northeast Energy Efficiency Partnerships put it, the marketplace will present an “easy, affordable choice to decarbonize” — a utopia he acknowledges we have yet to reach.

No matter the benefits that an electrified home powered by renewable energy provides, the expense can range from daunting to laughably unattainable. The IRA seeks to address these inequities by providing billions of dollars in funding, much of it targeted at those without the means to make the transition off fossil fuels. That money is expected to become available in the months ahead and could, for example, cover the entire cost of a heat pump or induction stove for low-income families. Some states or cities also offer income-based financing — in Vermont, for instance, interest rates start at 0 percent.

One of Wyent’s favorite suggestions, that almost anyone can take, is to buy an induction hot plate, often for less than $100. They are essentially a single-burner induction stove and, she said, “an electrification project that works for renters, too.” Energy audits are another great place to start, she suggested, as they can pay for themselves in utilities savings (plus there’s a federal tax credit of up to $150). But even for homeowners ready to take larger steps, the process can entail a lot of hand-wringing.

“More guides would certainly be helpful,” said Wyent. I turned to my spreadsheet to help maneuver the maze.

As I tweaked the cells, they quickly showed me that, if we were to go solar, installing the full system made the most financial sense. Although only putting panels on the front was tempting, installation costs wouldn’t drop proportionally. Certain design, permitting, wiring, and other outlays are largely fixed, making each panel successively cheaper. Assuming they operate for the 25 years they’re warrantied, going all-in would fix our electricity rate at $0.136 for 6,900 kWh annually. Doing just the front system would raise that figure to $0.142.

To evaluate the returns on a full system, I assumed our electric rate would continue rising at the state average of 2.28 percent annually and that our system’s productivity would degrade at the warrantied rate of 0.5 percent per year. Given that, the system would pay for itself in about 17 years and net more than $14,000 in energy cost savings after a quarter-century, for an annual rate of return of around 2 percent on our initial investment. That doesn’t factor in labor costs for any repairs (the warranty only covers parts) or the expense of replacing our roof earlier than planned. Financing the system at current interest rates — which are currently starting around 7 percent — also would cut into any financial gains. Paying cash is offset by the opportunity cost of doing something else with that money, such as investing in the stock market, which often sees long-term annual returns north of 8 percent.

Perhaps most relevantly, the climate benefits of going solar are limited in Vermont, because the grid is already so clean. Rewiring America’s model showed that our system would eliminate about a ton of carbon emissions annually, or roughly what a car generates driving 2,500 miles. Given our other concerns — from aggressive sales tactics to the need to replace our roof — we decided to hold off until we can find a way of bringing the overall price down. We may also explore community solar, which allows individuals to invest in larger projects.

“You’re in a particularly unfavorable area for rooftop solar to net out economically,” Wyent said. The technology makes more sense for people in other locales; she lives in California and estimates a household with a $500/month electricity bill in Los Angeles can save $62,000 over 20 years with a $0 solar loan. “The investment makes sense on financial merit alone.”

Although disappointed that solar didn’t work out, we found comfort knowing we didn’t have to spend tens of thousands of dollars right before our baby arrived. And we remained optimistic about heat pumps. But that math was a bit more complex, so we turned to Efficiency Vermont for help. Almost immediately, senior engineering consultant Matt Sharpe noticed that our design, with two condensers and five heads, wasn’t as efficient as it could be.

The ideal ratio for air-source heat pumps is one outdoor unit for every indoor unit, Sharpe explained. This ensures that the system is running steadily, rather than in short, inefficient spurts. But that isn’t always achievable, especially with larger systems such as ours — which would require an unsightly five outdoor units around our home. Instead, he suggested installing three condensers, one for each floor, and ductwork in the attic to reach the upstairs bedrooms. Beyond being tidier, it would consume 30 percent less energy than the initial proposal. Although the redesigned system would run $3,000 more, the city offers an extra $1,750 in rebates for ducted systems like this, and making this switch would reduce our annual heating costs by about $600, to around $1,100, accelerating the payback period.

This would bring the operating costs of heat pumps to about the same as the gas boiler. And, in the long-run, it would likely lead to savings, several experts told me. As more people ditch natural gas, they said, the cost for remaining customers could rise more quickly than electricity rates. “Both sides are going to be trending more expensive … [but] electricity rates are historically much more stable than natural gas prices,” said Lis.

Still, there is little chance we’ll recoup our $15,000 investment in heat pumps on operating costs alone. That doesn’t include the gas hookup fee of 88 cents per day that we pay to keep the boiler on standby, which Efficiency Vermont recommends doing at least for a couple of winters to ensure the heat pumps can handle the load job on the coldest days. (We plan to keep the baseboard heaters on the first floor awhile longer for that reason.)

Phillip Martin

Of course, the new ductwork and wiring will outlive the heat pumps; that’s money we won’t have to spend again. And eventually, heat pumps allow us to get rid of the baseboard heaters, which I find unsightly and limit how we arrange our furniture. Heat pumps also provide air conditioning, which we’d been poised to purchase as Vermont summers grow hotter with each year. That would be an outlay we could sidestep.

Removing the one-time expenses brings the price tag of our heat pumps to around $10,000. That’d be an easy choice if our boiler was broken, as a gas system plus an air conditioner would be about the same outlay. But because it could last another decade or two, that reasoning is largely moot. From a climate perspective, though, getting rid of gas is a bonanza.

“The heat pump is the biggest emissions saver in your home,” said Wyent. Over a 15-year lifespan, ours could eliminate about 54 tons of carbon dioxide emissions. A 2022 study published in Nature calculated the societal damage of each metric ton at $185, which nets $9,990 in abated harm and makes the switch a justifiable public good. Research has also shown that people are more likely to make climate-related changes in their behavior if they see others do it first.

Ultimately, we signed the paperwork.

Just before Christmas, we cut a check to Phillip Martin of Red Merle Mechanical and scheduled him for early January. Then we put the electrician on notice that he would need to hook up the heat pumps — a conversation that left me queasy.

He asked for the model numbers of the units, hung up to do the math, and called me back. “Bad news,” I recall him saying. Our additions — the stove, the dryer, the heat pumps, and an electric vehicle charger — were pushing our home’s 200 amp panel beyond its maximum capacity. It was exactly the sort of problem that Wyent had said could happen— and an upgraded panel would be at least $5,000.

The terror very nearly caused me to cancel the whole project. Amid my panic, I called Sharpe at Efficiency Vermont, who eased my worries. The problem, he reassured me, is both common and relatively easy to remedy with what’s called a circuit splitter, which allows two devices to safely use a single breaker. It reduces the maximum load on the panel by automatically alternating between two high-powered appliances that typically would not be used at the same time — say, an induction stove and an electric vehicle charger. (We typically charge our plug-in hybrid overnight.) It would be just $750 to install one.

With disaster averted, Martin showed up in his white truck, pulling a trailer laden with shiny heat pump parts. His first job was to run the ductwork in the attic and cut vent holes in the ceilings. We scheduled the work for while we were out of town and out of his way. I got a text message telling me our home’s thick plaster ceilings were chewing through drill bits and saw blades. Eventually he got through, installed the ducts, and then lined up the condensers in a neat row under the deck. We came home in time for the final wiring.

Phillip Martin

“I don’t know who’s more excited, me or you,” Martin said as he programmed the thermostat. With a rush of warm air, our heat pumps whirred to life. That night, the soft hum of a fan replaced the clanking of our baseboard system. In the morning, my wife and I took a saw to the water lines feeding the upstairs baseboard heaters and tossed them into a pile in the backyard. Removing them meant we could finally set up our baby nursery. And, with every cathartic heave, we weaned ourselves off natural gas. When we were done, I switched the boiler off.

Then came a call I didn’t expect so soon. Our neighbor had seen Martin’s truck in our driveway and wanted to hire him. Within weeks, she had heat pumps too. My father says he’s next.

This story was originally published by Grist with the headline Here’s what happened when two climate reporters tried to ditch natural gas on Mar 21, 2024.