Recycling your automobile floor mats, made from a recyclable thermoelastic polymer (TPE), is challenging due…

The post Recycling Mystery: Automobile Floor Mats appeared first on Earth911.

Category Added in a WPeMatico Campaign

Recycling your automobile floor mats, made from a recyclable thermoelastic polymer (TPE), is challenging due…

The post Recycling Mystery: Automobile Floor Mats appeared first on Earth911.

This story is published in partnership with The Fuller Project.

As Nour feeds another half-finished pair of pants through her sewing machine, her arms begin to shake. Amid the whir of fans, her T-shirt sticks to her like skin. She fights to focus, knowing full well her target of up to 100 pieces an hour isn’t going to hit itself.

“I am completely soaked in sweat,” the 38-year-old says of her work shifts. “The heat makes me exhausted.”

Nour, who asked to use a pseudonym out of fear of reprisal from her employer, works at Yakjin, a South Korean-owned garment factory in Cambodia. More than 2,500 employees here stitch apparel for major U.S. giants like Walmart and Gap. Workers at Yakjin say the heat often leads to near-fainting episodes, fatigue, and dehydration. With no windows, the air feels stifling but their requests for fans are at times ignored.

Workers at three other factories in Phnom Penh, the country’s capital, producing clothes for brands like Primark, H&M, and Old Navy (owned by Gap Inc.), told similar stories of worsening heat.

Around the world, fashion’s mostly female labor force is grappling with working conditions made increasingly unbearable and unhealthy by climate change. Women picking cotton in India’s sun-baked fields are toiling in temperatures of roughly 113 degrees Fahrenheit, while workers in Ghana’s Kantamanto — one of the world’s largest secondhand markets where clothing discarded by Western consumers is resold — are losing vital wages when flooding prevents trade. Nour is just one of nearly 1 million garment workers in Cambodia, a country that has experienced roughly 1.4 degrees F of warming per decade since the 1960s.

Fashion has had a devastating impact on the planet, producing more greenhouse gas emissions than aviation and shipping combined. So far, labor experts say, the more than $2.5 trillion industry has mostly focused its climate change efforts on mitigation, such as using more recycled fabrics, while largely ignoring how it impacts workers.

“[Labor] violations in factories are so gross, as in so widespread, and so awful … that that’s where the attention has been,” said Liz Parker, an associate member of Clean Clothes Campaign, an Amsterdam-based alliance of labor unions and nongovernmental organizations. “But workers are suffering from heat stress, from flooding, from water pollution … and we need to protect [them] from that as well.”

To expose how climate change is impacting workers throughout fashion’s supply chain, The Fuller Project tracked products from several brands — including Walmart, Primark, H&M, Gap, and Old Navy — across several countries. At each stage, women play a vital role in the global business of fashion, yet their livelihoods — and lives — are being increasingly threatened by extreme weather.

Cotton fields appear outside the car window an hour into the drive from Ahmedabad, capital of Gujarat state on India’s western coast. In every field, a woman in a sari is scooping cotton blossoms into a bag, spots of bright color that punctuate green fields topped with white fluff.

Roshan Osmanbhai arrives at 7 a.m. daily and ties a strip of cloth around her head to protect it from the sun. By midday, the temperature will hit more than 80 degrees F. The last week of January is supposed to be the height of winter in Gujarat, with average temperatures hovering around 68 degrees F. She hasn’t felt that traditional winter for years.

India is the world’s biggest grower of cotton after China. Six million farmers make a living from the sector, most of them women, according to Better Cotton, a nonprofit that promotes sustainable production. Cotton’s global supply chain is complex and lacks transparency, but Primark and H&M both confirmed they source from India. Walmart, Gap, and Old Navy didn’t respond to The Fuller Project’s requests for comment, but nonprofits monitoring supply chains said they likely do as well.

“If you’re in the apparel business … you have to come here,” said Ashis Mondal, former director of Action for Social Advancement, an Indian nonprofit supporting small farmers. “You have no other option.”

Across the region, the farms might be run by women, but few of them own the land they cultivate. The precarious nature of their work is exacerbated further by the changing climate, with summers arriving earlier and monsoon rains delayed or declining, damaging crops. India recorded extreme weather events on nearly 90 percent of the days in the first nine months of 2023, according to The Centre of Science and Environment, a research organization based in New Delhi, killing nearly 3,000 people and ruining almost 5 million acres of crop area.

In Gujarat last year, summer rolled in before March, the women said. The temperature shot up to roughly 113 degrees F before anybody knew what to do. Women farmers complained the heat was making it hard to carry on. “The heat makes our skin itch,” said Jessuben Jhapra, a 49-year-old farmer. “Heat rash can erupt all over the body. Our eyes are under enormous strain.”

The weather patterns have invited new and unfamiliar pests, requiring pesticides that have created further health problems for the women. Most own protective gear — gloves, boots, goggles — but don’t always use them when it’s hot. Two years ago, Alayben Zilriya, a 55-year-old farmer with sharp cheekbones and thin-rimmed spectacles, sprayed pesticides on the plants using her bare hands. She got such a severe reaction that she had to visit the doctor for treatment. Today, the skin on her hands is still shriveled, her nails grayish.

Excessive temperatures can do serious harm to humans. Heat exhaustion sets in when too much water and salt is lost, usually due to excessive sweating. Symptoms include nausea, dizziness, thirst, and palpitations. It can be hard to think clearly — hot weather is linked to reduced cognitive function, judgement errors, and higher risk of occupational injury.

For Nour, this sounds familiar. Even though drinking water is available at her factory, she feels dehydrated and has little energy to work. When it’s hot she takes more toilet breaks but misses her hourly targets and says her supervisors at Yakjin become verbally abusive.

“They curse or insult us,” she explained. “They blame us.”

Workers at Yakjin interviewed by The Fuller Project said they often feel ill or faint. Ry, 38, who has been employed at the factory for over a decade, thinks the heat is getting worse. Climate change is part of the problem, he says, but also fans aren’t maintained or replaced. While the building has fans that blow mist to keep workers cool, they do not reach all employees. For over two years, Ry has asked the factory for more, but says his requests have fallen on deaf ears.

Only a small handful of Cambodia’s roughly 1,300 garment factories have air conditioning, according to Seang Yot from The Coalition of Cambodian Apparel Workers’ Democratic Union, or C-CAWDU.

At lunchtime, Yakjin employees hang cloth above their heads in the outdoor canteen for extra shade. In heavy rains during the wet season, the area floods, as does the factory, workers told The Fuller Project. Cambodia is already highly vulnerable to flooding, including flash flooding, but projected climate change trends indicate this is only set to get worse — affecting tens of thousands more people each year by 2030. Workers are concerned about electric shocks as flood water comes in contact with the factory’s electrical systems, said Nour, though no one has been hurt yet.

“Anything involving money is always a problem,” explained Ry, who also asked to use a pseudonym. “The factory managers don’t care about how heat impacts us, only that we speed up and work faster.”

In an email, Yakjin Cambodia’s management said the factory maintains “a comfortable indoor temperature with cooling and ventilation systems,” including fans and air conditioners, but said there was no AC in the sewing line.

They said there have been no reported cases of fainting in the past two years, and that exhaustion could have many causes including inadequate healthcare, exercise, and lack of sleep, as well as heat.

There are grievance mechanisms in place for workers and no one had reported supervisors becoming verbally abusive when production targets were missed. Yakjin said the factory does not flood during the rainy season and there was no risk of electric shock.

Walmart, which sources from Yakjin, said it “does not tolerate unsafe working conditions” and is looking into the matter.

While Cambodia has always been hot, extreme heat now presents a major threat to human health. The country’s garment sector is particularly vulnerable to climate change because it emerged largely ad hoc with little oversight, according to a 2022 report led by Laurie Parsons, senior lecturer in geography at Royal Holloway, University of London.

Many of the factories, for example, are technically warehouses. “They’re not built for humans,” said Parsons. Most are also privately rented, which means factory owners have little power — or incentive — to implement changes, added Yot.

Cambodia’s labor law sets no limit on workplace temperatures, saying only that they must be “reasonable for employees.” In neighboring Thailand, with a similar-sized garment industry, the maximum is 93 degrees F wet-bulb temperature (a way of measuring heat stress that takes into account factors like temperature and humidity, among others).

Over two days, The Fuller Project asked a garment worker to measure temperatures using a digital thermometer in the sewing section of Jade Sun Garment, a factory producing for brands like Primark, Old Navy, and George, a British clothing line sold widely in Walmart. Recordings taken by a garment worker in February, one of the cooler months, hit 97.7 degrees F.

During the hottest months, from April to May, the country’s daytime outdoor temperatures can soar above 104 degrees F. Leakhena, a soft-spoken sewer who’s worked at Jade Sun for several years, often feels “nearly unconscious” during this period. “We need more oxygen,” she explained. “I cannot breathe properly.”

The water provided by the factory isn’t clean either, she said. “It smells a lot. When we drink water from that tap it gives us a sore throat.”

In response to inquiries from The Fuller Project about workers’ claims, Gap Inc. said it is opening investigations into Yakjin and Jade Sun Garment and will take appropriate action to remediate any breach of its policies. Primark is aware of the issues raised in connection with Jade Sun Garment and is in the process of “supporting remediation” with its management, adding that the safety of workers in its supply chain is “extremely important” to the company. Jade Sun Garment and George did not reply to multiple requests for comment.

In an email, Heng Sour, Cambodia’s Minister of Labour and Vocational Training, said the government is “deeply concerned” about worker welfare. He said The Fuller Project’s temperature recording at Jade Sun Garment offered a “limited view” because it used a single thermometer but pointed to the need for a “more detailed analysis to accurately assess and respond to temperature conditions.” The government is also in the process of “potentially” establishing maximum workplace temperatures and since being contacted has accelerated the deployment of additional cooling systems to factories.

Once their shift is over, women return home — yet there is no reprieve from the soaring temperatures. Many live in privately rented dormitories, often single-bedroom dwellings with low, metal roofs and little protection against extreme weather. Several workers described them as virtually unlivable in the heat.

“I want to see change,” said Leakhena, who also asked to use a pseudonym for fear of reprisals. “The heat is making us more exhausted every day. We don’t know what impact it will have on our health after five or 10 years. And by that point, it’s already too late.”

Inside Accra’s bustling central business district lies Kantamanto. A sprawling complex packed with vendors who sell what’s known locally as obroni wawu or “dead white man’s clothes.”

Ghana was the largest importer of used clothing in 2021, with $214 million worth of garments passing across its borders. When consumers in the United States or United Kingdom donate their old T-shirts, only 10 to 30 percent are resold in stores. The rest disappears into a vast network, often ending up here, West Africa’s hub for used garments from the West. In Kantamanto, stalls sell clothing from Primark, H&M, Walmart, Gap, and Old Navy.

Young women and teenage girls move through the market balancing 120-pound bales of clothing on their heads. Known as kayayei, they transport bales from importers to stalls, storage, and disposal sites, earning 30 cents to $1 per trip. The market’s narrow aisles don’t allow for motorized modes of transport, so the women play a crucial link in the secondhand supply chain. Their work frequently causes neck and spine injuries, said Liz Ricketts, co-founder of The Or Foundation, a Ghana and U.S.-based nonprofit. They also face sexual violence, including rape, and are at high risk of unplanned pregnancies, according to the United Nations.

Many are here because climate change has made farming in their villages unviable, but the cities have proven to be no refuge either. Ghana is experiencing more intense and frequent flooding and storms as global temperatures tick up. In Kantamanto, clothing waste clogs the gutters, which exacerbates the flooding, says Ricketts, and leads to an increased risk of cholera and malaria.

The market is open every day but Sunday. When clouds gather, 18-year-old Mariam Karim starts to worry. She earns roughly $14 a week carting bales of second-hand clothes from trucks, which covers her basic needs such as rent and food. During the rainy season, fewer customers show up and the market shuts roughly twice a month from flooding, according to Ricketts, often leaving women without pay.

A downpour can also mean no sleep. “Flooding at my home is common,” said Karim, who lives near the market in a wooden, makeshift dwelling. “I will usually scoop the water out of my room until it subsides. It is scary because colleagues have even lost their lives and properties.”

West Africa is a climate change hotspot and Accra’s low elevation makes it particularly vulnerable. After more than three decades working at Kantamanto, it’s something Daniel Ampadu, vice chairman of the Kantamanto Used Clothing Association, has seen with his own eyes.

“I am old enough so I can tell you that these days, so much rain comes…and many places, especially our market, gets flooded,” he said. “This wasn’t the case 30 years ago.”

Of the five brands examined across India, Cambodia and Ghana, only Primark and H&M provided details in response to queries about what they are doing to protect workers in their global supply chain from climate change. Primark said it knows it must “act to mitigate” the causes and effects of climate change and support their supply chain partners in similar efforts, such as educating farmers in their Sustainable Cotton Programme, a training scheme. H&M said it is aware of the impact that climate change has on the people in its supply chains and “constantly review and adapt” the scope of its climate-related risks.

For decades, the fashion industry’s exploitation of workers in low-income countries has been well documented. But a new challenge now presents itself: Who will protect them from a climate crisis that the very same industry helped bring about?

Better Factories Cambodia, a partnership between the International Labour Organisation, the UN’s labor agency, and the International Finance Corporation, has repeatedly recorded what it says are unacceptable workplace temperatures during inspections. Although some factories have invested in improved lighting and better ventilation, most need to do more, it says. More recently, fashion brands involved in Action, Collaboration, Transformation, or ACT, a global agreement aimed at transforming the garment industry, have begun to discuss ways to solve the heat problem for its workers, said Yot. Unless extreme heat and flooding are addressed, countries vital for fashion production, including Cambodia, risk losing $65 billion in export earnings and 1 million potential jobs by 2030, according to research by Cornell University’s Global Labor Institute.

“The buck stops always with the brands,” said Parsons. “[But] it’s kind of like pushing an open door… They’re like, yes, we should think about this but they haven’t yet.”

For Nour, she’d simply like to feel cool air on her face. Or the freedom to catch her breath. After work, she showers, washing away the sweat. For a brief moment, she feels alive, before being engulfed by the factory’s heat once more.

Additional reporting by Sineat Yon

The Fuller Project is a non-profit newsroom dedicated to the coverage of women’s issues around the world. Sign up for the Fuller Project’s newsletter, and follow the organization on X or LinkedIn.

This story was originally published by Grist with the headline The world’s garment workers are on the front lines of climate impacts on May 2, 2024.

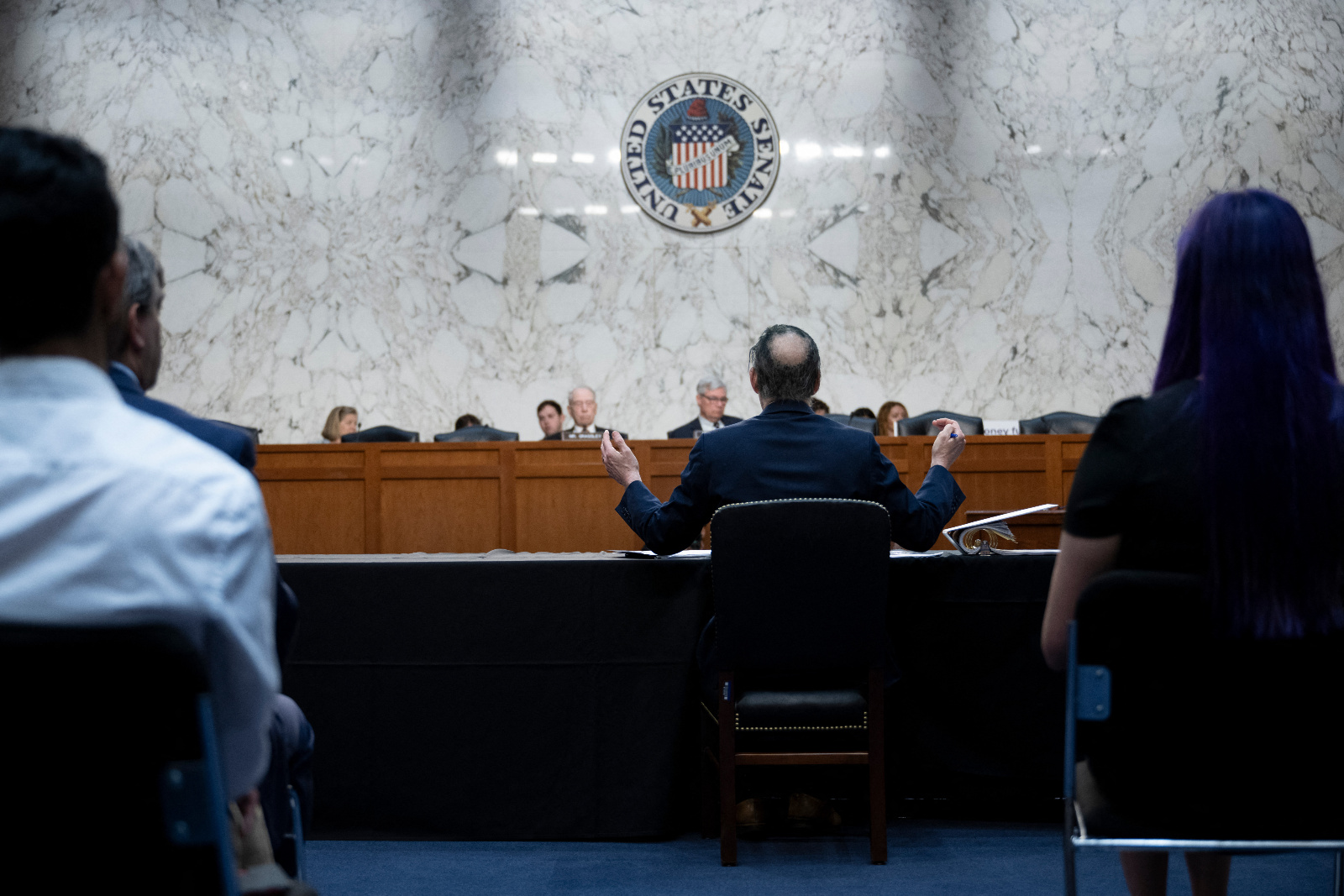

A congressional hearing on the fossil fuel industry’s “evolving efforts to avoid accountability for climate change” turned into a spectacle on Wednesday morning as lawmakers in Washington, D.C., grilled a panel of experts on wide-ranging — and often irrelevant — topics. The thousands of internal oil company documents released before the hearing, however, contained some bombshell findings.

One of the biggest revelations is that BP executives understood that natural gas, which the company promoted as a “bridge” or “destination” fuel to a cleaner future as coal declined, was incompatible with the goals of the Paris Agreement signed in 2015. “[O]nce built, gas locks in future emissions above a level consistent with 2 degrees,” at least without widespread carbon capture technology, according to a comment on a draft outline for a speech by BP’s CEO in 2017.

“This is the first evidence I’ve seen of them acknowledging internally, at the highest levels, that they know this — natural gas is a climate disaster — and yet, they still promote it,” said Richard Wiles, president of the Center for Climate Integrity, an environmental advocacy organization.

At Wednesday’s hearing, Senator Sheldon Whitehouse, a Democrat from Rhode Island, invited expert witnesses to talk about the industry’s attempts to shape media coverage and academic research and allegations that they misled the public through deceptive advertising. But Republican lawmakers went off-script, asking questions about boreal forest fires and alleging that reducing fossil fuel production would result in Americans “having to sell blood in order to pay their electricity bill.” At one point, Senator John Kennedy from Louisiana read a list of old Twitter posts in an attempt to discredit Geoffrey Supran, a climate researcher who testified at the event, apparently without realizing that the posts were not written by Supran, although he did retweet one of them.

The hearing was the outcome of a three-year congressional investigation that sought to uncover new information about fossil fuel companies’ history of spreading disinformation about climate change. The first hearing, in October 2021, focused on an early chapter of that history, the 1970s, and drew testimony from executives of BP, Chevron, Exxon Mobil, and Shell, as well as two industry lobbying groups — the American Petroleum Institute and the Chamber of Commerce.

Now, lawmakers have turned their attention to recent history. Ahead of the hearing, they released some 4,500 subpoenaed documents dating back to 2015 that show how oil companies’ internal discussions about the Paris Agreement, methane emissions, and investigations into their own climate denial have diverged from their public statements. The new evidence, summarized in a 60-page report, could be critical for lawsuits alleging that oil companies lied to the public about climate change, since they provide evidence of ongoing deception.

Internal documents show that BP recognized the risks associated with producing methane, a potent greenhouse gas that frequently leaks from old oil and gas wells. The company sought to respond to bad press around methane with a $1.1 million communications campaign, according to a draft presentation marked “confidential” from 2018. One of the pillars was to “harness excitement around renewables by positioning gas as the perfect partner,” including plans to fund research from Imperial College London “highlighting [the] role of gas as a friend to renewables.” The following year, when a study found that methane leaks can outweigh the fuel’s emissions-efficiency benefits, a BP executive wrote in an email that the findings were “quite concerning to us as another blow against natural gas.”

The documents also suggest that oil companies’ support for the Paris Agreement was superficial. Executives from Exxon and BP privately doubted that limiting global warming to 2 degrees Celsius (3.6 degrees Fahrenheit), the aim of the international climate accord, was achievable, even though they publicly voiced support for it.

Other sections of the report detail the fossil fuel industry’s resistance to U.S. policies to reduce carbon dioxide and methane emissions, as well as their extensive promotion of low-carbon technologies that they didn’t think had much of a future. Exxon Mobil, for example, has heavily promoted its investments in carbon sequestration despite acknowledging internally that it does not plan to deploy the technology at the scale needed to avert dangerous levels of global warming. The company also spent $175 million to advertise its research into algae biofuels despite employees acknowledging that the possibility of actually putting the technology into large-scale practice remained “decades away” and that the ads were potentially misleading.

The documents also shed more light on the $700 million that BP, Chevron, Exxon, and Shell spent on academic research programs at universities including Princeton, Harvard, Stanford, and the Massachusetts Institute of Technology between 2010 and 2020. The funding was part of a philanthropic effort to “gain access to policymakers and influential thought leaders,” according to the report. Additional documents suggest the companies have tracked critics in “weekly activists reports” and attempted to quash news stories about them.

During the hearing, Representative Jamie Raskin, a Democrat from Maryland, lamented the fossil fuel companies’ efforts to mislead the public rather than warn them about the consequences of their products. “They could have been the environmental Paul Revere,” he said. “But they were more like Rip Van Winkle and wanted everyone to go to sleep for a century.”

In response to Grist’s request for comment, BP and the American Petroleum Institute did not address Democratic lawmakers’ report but affirmed their commitment to moving toward renewables. BP said it is “investing in today’s energy system while helping to build out tomorrow’s.”

A spokesperson from Exxon Mobil said the report’s “tired allegations … have already been publicly addressed” in previous congressional hearings and in court, and pointed to the company’s efforts to reduce emissions. A spokesperson from Shell said documents highlighted in the report “are evidence of Shell’s efforts to set realistic targets … and meaningfully participate in the energy transition.” Chevron and the U.S. Chamber of Commerce did not respond to Grist’s requests for comment.

The results of the investigation could end up supporting attorneys general who have sued the fossil fuel industry. Oil companies are currently facing around 30 lawsuits for deceiving the public about the consequences of burning fossil fuels. Those suits, filed by state and local governments and Native American tribes, are moving closer to trial after years of delay. Some of them have drawn on subpoenaed documents released by the House Committee on Oversight and Accountability in 2022. The new evidence released this week, with its focus on the last decade, “really adds to the existing evidence base in the critical phase that’s going to be needed as a proof point in these cases,” Wiles said.

There is likely much more to uncover. During the hearing, Raskin said companies used a “paper blizzard tactic,” overwhelming investigators with hundreds of thousands of emails, newsletters, and other “fluff documents.” He alleged that thousands of documents were withheld or heavily redacted by oil companies to hide relevant information.

“If the companies had actually complied in good faith,” Raskin said, “who knows what else we might have discovered.”

This story has been updated with a clarification on social media posts reshared by Supran.

This story was originally published by Grist with the headline New documents show oil executives promoted natural gas as green — but knew it wasn’t on May 2, 2024.

On the evening of August 8, hours after a wildfire ravaged West Maui, Maui County’s top emergency management official, Herman Andaya, texted his secretary to ask about the status of other fires across the island.

“Still burning,” she replied.

“Wow … Lol,” Andaya texted back.

The messages were released in mid-April as part of a new state report analyzing the government’s response to the fire that ripped through Lāhainā killing more than 100 people, making it the deadliest wildfire in modern U.S. history. Documents, text messages and interviews reveal slow, poor communication between government agencies, causing hours of delay for leaders, like Andaya, to realize the gravity and extent of the crisis.

Andaya, who resigned soon after the wildfire due to broad criticism for his lack of qualifications and his agency’s decision not to sound any sirens as the fire spread, was at a training in Honolulu the day it happened. The texts show that hours after the inferno engulfed the town, Andaya didn’t know if any homes had been lost and thought only a single business had been leveled. The fire burned more than 2,000 buildings, displacing thousands of people.

To Alyssa Purcell, a Native Hawaiian archivist from Oʻahu, the lack of urgency in top officials’ response to the community’s struggles feels familiar.

“It’s a pattern,” she said. “This is not new. And I think the text messages show that there’s such a desensitization on their part to our needs that there’s nothing else that we can do at this point except go to the highest possible platforms and stages that we possibly can.”

Two days before the report came out, Purcell flew to the United Nations headquarters in New York City to speak at the U.N. Permanent Forum on Indigenous Issues, urging those present to support the self-determination of Native Hawaiians like herself.

“The 2023 Lāhainā wildfires exposed a systemic disregard for Indigenous rights,” said Purcell, who is a member of the Ka Lahui Hawaiʻi delegation, a group working to advance Native Hawaiian sovereignty. “Hawaiian families are struggling with disaster capitalism, where corporations and developers are using the aftermath of the fires to acquire land, develop properties, and initiate projects that are not in line with the needs of Indigenous communities or sustainable practices.”

The wildfire’s unprecedented destruction underscored the stakes of the group’s decades-old appeal for international support for Native Hawaiian self-determination. In her remarks this year, Purcell called for the U.N. to relist Hawaiʻi as a non-self-governing territory. That list includes more than a dozen territories — Guam, French Polynesia, and New Caledonia, to name a few — whose people still haven’t yet achieved self-government, either by obtaining independence or choosing to join another country.

The Hawaiian Islands were removed from the United Nations list of colonies after Hawaiʻi residents voted to become a state in 1959. But Hawai’i had only been given the option of statehood over their previous status as a U.S. territory. Unlike other island nations like Palau, Vanuatu, and Fiji, the Indigenous peoples of Hawaiʻi were never given the option of independence after the United States overthrew the Hawaiian monarchy in 1893.

“If you go back to the root of all these seemingly disparate problems, you’ll find very, very quickly that the root of all of it is the lack of self-determination,” Purcell said.

Take Lāhainā. In the decades prior to the overthrow, the coastal community was the capital of the Hawaiian Kingdom. Hawaiian royalty lived on a sandbar in the midst of an expansive fishpond along Maui’s leeward coast. But sugarcane owners in the 19th century diverted water from the wetlands to their fields, forcing many locals to abandon subsistence farming of crops like taro and breadfruit. Eventually, the fishpond was paved over for a parking lot and baseball field, and when last year’s wildfire came, the former wetland was arid and primed to burn.

The new state report on the Lāhainā wildfires found that as tourism and real estate have replaced large-scale agriculture as main economic drivers in Hawaiʻi in recent decades, landowners have left large tracts of land fallow and filled with highly flammable invasive grasses.

“The removal of active agriculture and the subsequent accumulation of highly combustible standing dead fuel on unmanaged lands is leading to more and larger fires,” the report said.

These destructive wildfires are modern and 99 percent human-caused, the report said.

“Unlike Indigenous uses of fire in continental fire-adapted ecosystems — where systemic and regular burns were used for millennia as a tool for forest health, regeneration, and swidden agriculture — the intentional use of fire in Hawaiʻi was largely limited to the clearing of lowland agricultural fields, cooking, the burning of waste, and small ceremonial practices,” the report said. “Since Hawaiian forests are less adapted to fire and are often destroyed when burned, the cultural ramifications of increased wildfires in Hawaiʻi are significant.”

Brandi Ahlo, another member of the Ka Lahui Hawaiʻi delegation to the U.N. who attended the Permanent Forum with Purcell for the first time this year, sees the Lāhainā wildfire as the inevitable consequence of Indigenous land dispossession.

“It goes back into history and the loss of water and the fact that us as Kanaka, who live on the land, aren’t able to steward our own resources,” Ahlo said. “I think bringing awareness to an international arena and forum is really important for people to see and to spotlight, because if it can happen here in Hawaiʻi, who is to say that it can’t happen to anywhere else?”

Extreme weather events like the wildfire are expected to grow more frequent as climate change accelerates. State leaders in Hawaiʻi are still trying to figure out exactly what happened in Lāhainā last year and plan to release two more reports analyzing officials’ decisions and how similar tragedies could be avoided.

The state is also trying to figure out housing options for families rendered homeless by the disaster and has cut down on the amount of food they’re giving to more than 2,200 displaced families staying in hotels. People whose homes in Lāhainā were spared still can’t drink the water that was contaminated when the fire melted pipes.

A continuing concern is the potential for private interests to capitalize on the disaster’s aftermath by seizing more water and land, both highly contested limited resources on Maui long before the fires.

In the days following the fire, the state temporarily suspended water regulations in West Maui, benefiting a major local developer who had spent years fighting with Indigenous taro farmers over access to water. On the other side of the island, the state urged a court to allow corporations to divert more water from East Maui streams. The Board of Land and Natural Resources argued that limits on water diversion — limits imposed by the court after lawsuits from Native Hawaiian taro farmers asserting their right to the water — meant that there wasn’t enough water to fight fire in central Maui.

In April, the state Supreme Court issued a ruling saying the state’s arguments were based on zero evidence and made in bad faith.

“It seems the BLNR tried to leverage the most horrific event in state history to advance its interests,” the Hawaiʻi Supreme Court ruling said.

Meanwhile, the community is still reeling emotionally from the grief of the fire’s destruction.

“When I look at the Lāhainā fires, I see cultural destruction, degradation. I see people dying. I see their homes — homes that they’ve lived on for generations — perished in a minute,” Purcell said. “And when foreigners look at the situation, when business owners look at the situation, they see opportunity.”

This story was originally published by Grist with the headline After Lāhainā, Indigenous peoples call for independence on May 2, 2024.

Plastic — once seen as a marvel of modern science with uses from packaging to textiles — is now a scourge polluting our waterways, exposing us to PFAS “forever chemicals” and making its way into our bloodstreams in the form of microplastics.

Plastic production doubled worldwide in the 20 years prior to 2019, according to a team of researchers writing in The Conversation. Up to 20 percent of the planet’s oil production could be taken up by plastic manufacturing and processing by 2040, using 15 percent of the yearly carbon emissions budget.

“Most of the plastic we make ends up as waste. As plastic manufacturers increase production, more and more of it will end up in our landfills, rivers and oceans. Plastic waste is set to triple by 2060,” the research team said.

The study, “The New Plastics Economy: Rethinking the future of plastics,” was published by the World Economic Forum.

A Center for Climate Integrity report from earlier this year — The Fraud of Plastic Recycling — said the plastics industry was well aware that widespread plastic recycling was unrealistic, but led the public to believe it was feasible.

In The Conversation, the authors of the new study said plastics producers have promoted the idea that how much of their product is produced is irrelevant as long as we — the customers — recycle.

The researchers discovered that this is far from the truth. They found a direct correlation between plastic production and increased plastic pollution.

“[A] 1% increase in plastic production leads to a 1% increase in plastic pollution, meaning unmanaged waste such as bottles in rivers and floating plastic in the oceans,” the researchers wrote. “Not only that, but over half of branded plastic pollution is linked to just 56 companies worldwide. The Coca-Cola Company accounts for 11% of branded waste and PepsiCo 5%. If these companies introduce effective plastic reduction plans, we could see a measurable reduction in plastic in the environment.”

According to experts, it is estimated that an additional 53 million tons of plastic waste will end up polluting the world’s oceans each year by 2030.

“Plastics can cause real damage to our health. Our first exposure to them starts in the womb. In the seas, plastics can choke turtles and seabirds. On land, they can poison groundwater. Socially and economically, plastic pollution now costs us about A$3.8 trillion a year,” the researchers said.

The researchers looked at five years of litter audit data — global surveys of environmental waste — to get an idea of types of plastic waste and their volumes. The data included more than 1,500 audits from 84 countries. The audits found that 48 percent of litter was brand-name, while the remainder was unbranded.

To figure out production levels, the team looked at data reported by major plastics companies to a circular economy organization, then compared it with branded plastic pollution data.

They found that 13 companies each added one percent or higher to the overall branded plastic problem. The companies all produced beverage, food or tobacco products that were mostly packaged using single-use plastic.

Roughly 36 percent of plastic pollution worldwide comes from single-use plastics.

“Even when collected, single-use plastics are a difficult waste stream to manage as they have little or no recycling value,” the researchers wrote. “Then there’s the fact recycling is not a circle, as the famous logo might suggest. The more we recycle plastic, the more degraded it becomes. Eventually, this plastic becomes waste. If recycling and landfilling can only go so far, the missing piece of the puzzle has to be capping plastic production.”

The researchers said this would involve manufacturers being required to reduce their plastic use over time while adopting sustainable and safe alternatives as they come along.

They added that countries could set measurable goals for phasing out hazardous, non-essential and unsustainable single-use plastics like plastic bags, cutlery and take-away containers; work on designing sustainable and safe products to reduce demand for new plastic worldwide while increasing reuse, repairing, refilling and recycling; and invest in non-plastic substitutes and alternatives that have improved environmental, social and economic profiles like reusables.

“One thing is certain – current trends mean ever more plastic, and more plastic means more plastic pollution,” the researchers said.

The post Plastic Manufacturing and Processing Are Still Increasing, Study Finds appeared first on EcoWatch.

New research has found that the tropical Indian Ocean is warming at an unprecedented rate that could speed up this century if human-produced greenhouse gas (GHG) emissions are not reduced right away.

The accelerated temperature increase could have significant impacts on biodiversity — particularly coral reefs — as well as have wide-ranging socioeconomic effects.

“The future increase in heat content is equivalent to adding the energy of one Hiroshima atomic bomb detonation every second, all day, every day, for a decade,” Dr. Roxy Mathew Koll, the study’s lead author and an Indian Institute of Tropical Meteorology climate scientist, told Down To Earth.

According to the study, the temperature of the planet’s third-largest ocean experienced a basin-wide warming increase from 1871 to 2020. The average sea surface temperature in the 1870s was 79.6 degrees Fahrenheit, but had increased to 81 degrees Fahrenheit by the 2010s.

Ocean surface warming in the Indian Ocean — coupled with heat built up in the first 6,561.7 feet below — can have substantial effects on the region’s monsoon season, reported Down to Earth. The weather pattern brings roughly 70 percent of India’s yearly rainfall while affecting climate in other South Asian nations.

The increased warming could also cause more intense and frequent extreme weather like flooding and tropical cyclones, in addition to sea level rise from thermal expansion in the 40 countries that border the Indian Ocean. Koll pointed out that thermal expansion is responsible for more than 50 percent of sea level rise, exceeding that caused by sea ice and glacial melt.

“Marine heatwaves are projected to increase from 20 days per year (during 1970–2000) to 220–250 days per year, pushing the tropical Indian Ocean into a basin-wide nearpermanent heatwave state by the end of the 21st century,” the study said.

Marine heat waves can lead to coral bleaching, kelp forest degradation and seagrass loss. They can also contribute to the rapid intensification of tropical cyclones.

“These prolonged marine heatwaves will not only intensify cyclones but also affect fish migration, coral reefs, phytoplanktons and marine biodiversity,” Koll told Mongabay India.

The researchers looked at the ocean’s surface temperature warming and found it had increased at a rate of 0.12 degrees Celsius each decade from 1950 to 2020.

The most marked warming occurred in the northwest portion of the ocean, which includes the Arabian Sea, while the least warming was seen off the Java and Sumatra coasts, Down to Earth reported.

Warming in the Indian Ocean is also predicted to cause a decrease in the water’s pH levels from roughly 8.1 to 7.7 by 2100.

“The projected changes in pH may be detrimental to the marine ecosystem since many marine organisms — particularly corals and organisms that depend on calcification to build and maintain their shells — are sensitive to the change in ocean acidity,” Koll told Down to Earth.

The study said the most effective plan of action to mitigate current and future warming impacts is to build infrastructure that is climate resilient and reduce GHG emissions.

“The Indian Ocean, a climate change hotspot, faces rapid and strong increases in marine heatwave frequency and intensity unless global CO2 emissions are substantially cut,” said co-author of the study Thomas Frölicher, a University of Bern climate scientist, as reported by Down to Earth.

The post Indian Ocean to See ‘Rapid and Strong’ Increase in Heat Waves Unless CO2 Emissions ‘Substantially Cut’ appeared first on EcoWatch.

A team led by researchers at the University of California San Diego have developed a type of biodegradable plastic that can begin digesting itself when it makes contact with soil or compost.

The soft plastic material is a type of thermoplastic polyurethane (TPU), commonly found in memory foam products and soft products like cushions, floormats and even shoes. The updated TPU that researchers created includes spores of Bacillus subtilis. The bacteria remains dormant in the plastic until it reaches compost, where it interacts with nutrients and begins to break down the plastic.

“It’s an inherent property of these bacteria,” Jon Pokorski, co-author of the study and a nanoengineering professor at Jacobs School of Engineering at UC San Diego, said in a statement. “We took a few strains and evaluated their ability to use TPUs as a sole carbon source, then picked the one that grew the best.”

The research team combined the bacteria and the TPU in a plastic extruder, where the materials were melted and mixed together to create the pieces of biodegradable plastic.

Then, researchers tested the plastic by placing strips of it in compost. The team set up two compost areas with the same temperature, 37 degrees Celsius, and similar humidity levels of 44% to 55%. One area was sterile while the other was microbially active.

The results showed that the plastic reached over 90% biodegradation in a 5-month timeframe in both compost types. The researchers published their findings in the journal Nature Communications.

“What’s remarkable is that our material breaks down even without the presence of additional microbes,” Pokorski said. “Chances are, most of these plastics will likely not end up in microbially rich composting facilities. So this ability to self-degrade in a microbe-free environment makes our technology more versatile.”

Next, the researchers plan to continue to determine the feasibility of scaling up this development while also finding ways to speed up the biodegradation time. They also hope to try this method on other types of plastics.

While the development could help reduce the impact of new plastic products in the future, many scientists still underscore the importance of reducing plastic production altogether.

Steve Fletcher, director of the Revolution Plastics Institute at the University of Portsmouth who was not involved in the study, told BBC News, “Care must be taken with potential solutions of this sort, which could give the impression that we should worry less about plastic pollution because any plastic leaking into the environment will quickly, and ideally safely, degrade. Yet, for the vast majority of plastics, this is not the case.”

The post Researchers Develop a Plastic That Digests Itself appeared first on EcoWatch.

Negotiators wrapped up the fourth round of formal discussions over the United Nations’ global plastics treaty early on Tuesday morning, inching closer to a final agreement that’s intended to “end plastic pollution.”

Delegates made important progress on the treaty, the final version of which is due by the end of the year. They pared down a lengthy draft of the text and agreed on a formal agenda for “intersessional” work ahead of the next — and final — meeting, in Busan, South Korea, scheduled for November 25. That work will involve critical issues around funding the treaty’s provisions and identifying plastic-related chemicals that should be restricted.

The agenda, however, doesn’t mention the elephant in the room: whether and how the treaty will limit plastic production.

“Nothing happened that was particularly surprising, but this outcome is still quite demoralizing,” said Chris Dixon, an ocean campaign leader for the nonprofit Environmental Investigation Agency who attended the talks. Other groups called the outcome “disappointing” and said the negotiations had been “undermined by deep-rooted industry influence.”

Dixon and other environmental advocates have spent the past three meetings fighting for a treaty that addresses the “full life cycle” of plastics — meaning one that goes beyond waste management to limit the amount of plastic that’s made in the first place.

The world already produces more than 400 million metric tons of plastic per year, and fossil fuel companies are planning to dramatically increase that number over the next few decades. Plastics have been described as the fossil fuel industry’s “plan B” as the world pivots away from using oil and gas in transportation and electricity generation. This could have dire implications not only for plastic pollution but for the climate; according to a recent study, greenhouse gas emissions from growing plastic production could eat up one-fifth of the world’s remaining carbon budget by 2050.

Just because production limits aren’t on the agenda for ad hoc working groups, however, doesn’t mean they’re out of the treaty; it just means delegates may arrive in Busan less prepared to discuss technical concepts related to plastics manufacturing. Language about the “full life cycle” of plastics is still in the treaty’s mandate — which countries agreed on in 2022 — and throughout the draft text. Countries can also host unofficial discussions on the topic between now and November.

There’s already widespread support for addressing plastic production in the treaty. Dozens of countries supported a statement presented by Rwanda and Peru last week saying that a global plastic reduction target should be “a North Star” for the treaty. The paper suggested reducing production by 40 percent below 2025 levels by 2040. Another declaration, published on Monday and signed by 28 countries, called for the treaty to “achieve sustainable levels of production of primary plastic polymers.”

Dixon said translating that support into binding treaty text is a matter of “political commitment.” On Monday, production was “the first topic to get dropped” as delegates scrambled to agree on an agenda for intersessional work, she said. They were trying to avoid a repeat of the previous conference, which ended with no agenda at all.

Santos Virgilio, a delegate representing Angola, said during a panel on Monday that it is “too early to say” how his country and others will coax oil-producing states into accepting treaty provisions on plastic production. Saudi Arabia, Kuwait, and Qatar are among the countries most vociferously opposed to addressing plastic production as part of the treaty. Plastics industry lobbying groups also turned out in full force at the negotiating session to oppose production caps.

Chris Jahn, council secretary of the International Council of Chemical Associations, said in a statement on Monday that the industry is “fully committed to a legally binding agreement all countries can join that ends plastic pollution without eliminating the massive societal benefits plastics provide for a healthier and more sustainable world.”

Industry groups used the convening as a public relations opportunity, touting the benefits of plastic in ads placed throughout Ottawa. In a hotel, one collection of ads said plastics “save lives,” “deliver water,” and “reduce food waste.”

The United States has also resisted plastic production limits as part of the treaty. A State Department official told the Financial Times on Tuesday that “overly prescriptive approaches” could alienate “major producers or consumers of plastics.” Instead of cutting the supply of plastics, the U.S. wants to focus on reducing demand and improving infrastructure for recycling and reuse.

Despite frustrations, several observers noted a promising shift in the tone at this week’s negotiating session, compared to the previous meeting. “There was a different energy, it was more collaborative,” said Erin Simon, the vice president and head of plastic waste and business for the environmental nonprofit WWF. Bjorn Beeler, the general manager and international coordinator for the nonprofit International Pollutants Elimination Network, said it was “very significant” that the delegates were able to move from a 70-page “zero draft” of the treaty — a laundry list of options meant to represent everybody’s viewpoints — to a more formal version that’s been vetted by negotiators.

All of the most ambitious provisions of the treaty are still in the newly updated draft, Beeler said, meaning they’re still up for discussion. He also noted growing support for health-related aspects of the treaty, particularly a provision to limit potentially dangerous chemicals that are commonly added to plastics. Delegates agreed to create an expert group to focus on this topic during intersessional work. They tasked it with proposing a framework to identify the most problematic types of plastic and plastic-related chemicals, as well as product designs that increase plastic products’ recycling and reuse potential.

Although countries disagree on whether certain substances should be banned or just restricted, and which criteria should be used to identify such substances, there is more convergence on regulating chemicals than on most other issues. Even Iraq, a major oil producer, submitted a statement supporting the creation of two lists of banned and restricted plastic chemicals.

“Everyone knows there are hazardous chemicals in plastics,” Beeler said. Griffins Ochieng, the executive director of the Kenya-based Center for Environmental Justice and Development, said in a statement that a global plastics treaty that addresses chemicals in plastics “is an impetus toward eradicating plastic pollution.”

One other expert group will focus on finance — where to get funding to help developing countries transition away from single-use plastics and test plastics for hazardous chemicals, among other treaty objectives, and how to distribute that money. Some countries and many environmental groups support the creation of a dedicated fund to help poor countries implement the provisions of the plastics treaty. Others say it would be simpler to use an existing mechanism like the Global Environmental Facility, a multilateral fund that provides grants to support government projects.

With eight months remaining in 2024, delegates have a lot of work ahead of them if they want to wrap up a treaty by the end of the year, which is the goal countries agreed on when they decided to write a treaty in March 2022. Even if the treaty does not take its most ambitious form, it could still have a big impact. Policies to disincentivize the use of virgin plastic, for instance — like recycled content requirements — are relatively noncontroversial, and they could indirectly limit plastic production. Beeler said it’s also possible that new requirements on the measurement and disclosure of plastic production could eventually lead to production limits after the treaty is ratified.

Simon, with WWF, said she feels cautiously hopeful following this week’s meeting. The conference was “not a failure, and definitely not a win.” she said. “But it is progress.”

This story was originally published by Grist with the headline UN plastics treaty inches closer to reality as lobbyists tout plastics’ ‘massive societal benefits’ on May 1, 2024.

For several months last year, patrons of a Seattle coffee shop called Tailwind Cafe had the option of ordering their Americanos and lattes in returnable metal to-go cups. Customers could simply borrow a cup from Tailwind, go on their way, and then at some point — perhaps a few hours later, perhaps on another day that week — return the cup to the shop, which would clean it and refill it for the next person. If it wasn’t returned within 14 days, the customer would be charged a $15 deposit, though even that was ultimately refundable if the cup was returned by the end of 45 days.

Tailwind’s head chef, Kayla Tekautz, said her cafe started the program out of a desire to address the environmental scourge of disposable plastic foodware and other packaging, the vast majority of which cannot be recycled. It was a partnership with a reusable packaging and logistics company called Reusables.com, which provided Tailwind and another Seattle area store, Cloud City Coffee, with branded cups and a QR code-operated drop-off receptacle.

But the cafe quickly ran into trouble. It was “overwhelming” to explain the return system to every interested customer, Tekautz said. Many were hesitant to participate after learning that they could only return the cups to Tailwind or the other drop-off location, 6 miles away. Plus, Tailwind’s QR code reader kept malfunctioning, requiring repeated visits from a mechanic. At the end of last summer, Tailwind quietly ended the return program. “It just didn’t work,” Tekautz said. (Reusables.com didn’t respond to Grist’s request for comment.)

In an effort to reduce consumption of single-use plastic, Seattle has spent the past several years encouraging local businesses to offer reusable cups, dishes, utensils, and packaging. It has made some laudable progress. Concertgoers at the Paramount Theater and attendees of the Northwest Folklife Festival, for example, can now order their libations in reusable polypropylene cups. And since 2022, students at the University of Washington have been able to check out bright green reusable food containers from a company called Ozzi.

These programs are helping Seattle avoid single-use plastic and create a “waste-free future,” according to the city’s reuse website. It’s a target that’s being pursued by many American cities, and at the global level too. Disposable plastic foodware and packaging — which accounts for nearly 40 percent of all plastic production — can only be phased out if there are robust, efficient reuse systems to replace them.

But some businesses, like Tailwind, have struggled to get reusable containers off the ground, often because of the small scale and disconnected nature of existing reuse programs. Instead of pooling resources and employing just one or two large cleaning and logistics services, businesses have so far chosen among several competing initiatives — or in some cases, have created and run their own programs. The result is a slew of incompatible containers, specific to just a few stores or locations, and inefficient systems for gathering, washing, and transporting between customers’ homes, sanitation facilities, and storefronts.

Having so many companies creating their own designs and logistics can be expensive, causing them to miss out on economies of scale that could make reuse more affordable and easily adoptable. According to Ashima Sukhdev, a policy adviser for the city of Seattle, she should be able to “pick up a coffee from my local cafe, and then drop it off in the lobby of my office building. Or drop it off at the library, or at a bus stop.”

What Sukhdev is describing would represent a highly unusual level of coordination across company lines. At coffee shops, this would mean reusable mugs shared not only between Tailwind and Cloud City, but also Starbucks and Peets. For grocery stores, it could mean picking up a jar of olives at Safeway, dropping off the empty container at Walgreens, and then having the same jar refilled with jam and sold at Whole Foods. Achieving this would require companies to rethink the way they compete with each other and differentiate their products. It would also require big changes from consumers, who have been trained for 70 years to expect disposability in just about every aspect of daily life.

Experts say these changes are necessary. “For this solution to become a reality, you’re gonna need standards,” said Pat Kaufman, manager of Seattle Public Utilities’ composting, recycling, and reuse program.

Kaufman is currently on a yearlong sabbatical working for a nonprofit called PR3, which is trying to create those standards. The questions they’re facing are: What will standardized reusable packaging systems look like — and what will it take to get companies, and consumers, to adopt them?

Every year, the world produces about 400 million metric tons of plastic — almost entirely out of fossil fuels like oil and gas. Some of this is used in essential products like contact lenses and medical equipment, but a much greater fraction goes toward sporks, cups, bags, takeout containers, and other items that get thrown away after just a few minutes of use. Most of this plastic will never be recycled due to technical and economic restraints; more than 90 percent of all plastics get sent to a landfill or incinerator, or turn up as litter in the environment, where they degrade into microplastics and leach hazardous chemicals. Plastics manufacturing causes additional harms, including air pollution that disproportionately affects low-income communities and communities of color living nearby.

For all of these reasons, public pressure to cut back on single-use plastics has escalated dramatically in recent years. Many companies have responded by launching trials and pilot programs allowing customers to borrow and return reusable cups, bottles, trays, jars, and other containers. These include small players like Ozzi, as well as behemoth brands like Walmart and Coca-Cola. There have been “more trials than Donald Trump,” said Stuart Chidley, co-founder of a reusable packaging company called Reposit.

As in Seattle, however, their efforts have been siloed, making it hard for the reuse sector to grow. According to a recent report from the Ellen MacArthur Foundation, or EMF — a nonprofit that advocates for a “circular economy” that conserves resources — even companies that have pledged to dramatically scale down their use of plastics have only replaced 2 percent or less of their single-use containers with reusables.

“To realize the full benefits of return systems, a fundamentally new approach is required,” the authors concluded.

The EMF report focuses on reusable containers that you can return to the coffee shop, grocery store, or another drop-off point — known as “return on the go” — as opposed to those that consumers own and bring with them to stores. It says that three things need to happen to make reuse mainstream. First, companies have to achieve high return rates, so they don’t lose inventory when people steal or forget to return their containers. Second, they have to share infrastructure for washing, collecting, sorting, and delivery in order to achieve economies of scale. Third, reusable containers must be standardized. The third pillar makes the other two much easier to achieve, since it’s simpler to share logistics, scale up, and familiarize customers with reuse systems if they share common characteristics — for instance, if containers are designed with similar shapes, sizes, and materials.

To that end, PR3 has spent the past four years drafting standards for reuse systems, with a particular focus on container design. Through a “consensus body” composed of members from big business, the advocacy world, and government, PR3 is hoping to eventually certify the world’s first reuse standards under the International Organization for Standardization (known as ISO, to prevent confusion around different acronyms in different languages). This would lend legitimacy to the PR3 proposals, as the ISO maintains one of the world’s most widely accepted catalogs of standards. Others within its portfolio cover everything from food safety to the manufacturing of medical devices, and have been voluntarily adopted by many large companies and government bodies.

PR3 released a draft of its standards last year, and it’s been updating them behind closed doors since then. Specific standards on washing protocols are set to be published for public review this week, and the nonprofit hopes that its consensus body will vote to finalize standards for container design later this year.

PR3 released a draft of its standards last year, and it’s been updating them behind closed doors since then. Specific standards on washing protocols are set to be published for public review this week, and the nonprofit hopes that its consensus body will vote to finalize standards for container design later this year.

So, what makes a good reusable container system? It’s complicated. Containers have to hold up under the stresses of logistics and transportation. They have to be relatively inexpensive. Perhaps most intangibly, they have to seem reusable, so customers don’t accidentally throw them in the trash. This can be accomplished through design elements — like containers’ color, texture, shape, and weight — or through other means, like easily recognizable drop-off boxes for used containers. Some reuse advocates support deposit fees, in which customers pay a small amount, usually just a dollar or two, in order to borrow a reusable container. They get the deposit back once they’ve returned the container.

None of these features is guaranteed to work. In designing draft standards, PR3 has often had to make educated predictions about which ones consumers will respond to. And those predictions can have far-reaching implications. If you assume customers will frequently lose or forget to return their containers, for example, then it probably won’t make sense to design thick containers that are capable of withstanding hundreds of uses.

“In the real world, return rates vary wildly,” Claudette Juska, PR3’s technical director and one of its co-founders, told Grist. “You don’t want to design a container for 400 uses if it’s only going to be used four times.” The most recent version of PR3’s standards say containers must be designed to withstand at least 20 uses and reused in practice at least 10 times.

On the other hand, it may be counterproductive to design containers with the expectation that they won’t be returned. According to Chidley, with Reposit, cheap-looking and -feeling containers could actually cause low return rates, since people might be more careless with them. His philosophy is to use features like color, weight, and shape to communicate containers’ reusability, making it less plausible that people will confuse them for disposables.

PR3 doesn’t have much specific advice on these characteristics, but some entrepreneurs Grist spoke with said they’ve hit higher return rates through particular design choices. For Chidley, this means making containers “beautiful” through high-quality, heavier materials with stylish branding. His containers are available at Marks & Spencer grocery stores across England and Scotland. Lindsey Hoell, founder of a reusable container logistics company called Dispatch Goods and a member of PR3’s standards panel, has forgone sharp-edged takeout food containers in favor of ones with smoother edges that “feel fancier.” And because so many single-use plastics are either black or white, her containers are bright red. “There’s a lot of soft science of what makes a consumer feel like something is durable,” she told Grist. Her containers are available across most of the U.S., mostly through grocery and meal delivery programs like Blue Apron and Imperfect Foods.

To some extent, the discussion about expected use cycles and perceived quality is really just another way of asking what kinds of materials reusable containers should be made of: durable plastic or something else? Answering that question can bring into conflict businesses’ economic interests with concerns about health and the environment.

In the published draft of its standards from last year, PR3 recommended that reusable containers be “plastic-free,” citing plastic additives’ wide-ranging impacts on human health and ecosystems. Plastic can be cheap, light, and durable, but plastic-related chemicals have been shown to build up in people’s bodies and the environment, where they may contribute to hormone disruption, cancer, and reproductive harm.

PR3 panel members like Jane Muncke, chief scientific officer for the nonprofit Food Packaging Forum, supported the recommendation. “I don’t think plastics are suitable materials for reusable packaging,” she told Grist. She’s concerned about chemicals migrating into foods and beverages — especially hot, acidic, or fatty foods, which are better at soaking up some plastic additives. Durable plastics are also largely nonrecyclable; after being turned into new products a few times, they have to be thrown away or “downcycled” into lower-quality products like carpeting.

Still, many entrepreneurs and even the PR3 founders themselves have moved away from a hard-line stance against plastics. Hoell, for example, originally got into reuse because she was frustrated by plastic-strewn beaches in California — “I’m a surfer and I hate plastics,” she told Grist. She started out making stainless steel containers but soon discovered that rigid plastics had much lower up-front costs, giving her more wiggle room to deal with lower return rates. She didn’t have to worry as much about frequently lost, stolen, or damaged containers.

Plastic was also easier to transport because of its light weight, Hoell added, and she cited some analyses suggesting that it has a lower carbon footprint than alternatives like steel. (These findings are controversial, however; critics say it’s misleading to focus only on plastic-related carbon emissions and not the materials’ other dangers, like toxic chemicals leaching from landfills.)Dispatch Goods now only makes its containers out of polypropylene, a kind of plastic that’s generally considered more inert than others (although it can still leach hazardous chemicals). Other reuse logistics companies like R.world, which operates in Seattle and is also represented on the PR3 panel, have similarly opted for polypropylene containers instead of metal or glass.

At Seattle Pacific University, a reusable container program for students eating at the Gwinn Commons dining hall also uses rigid plastic. The containers’ low cost allows Sodexo, the school’s foodservice provider, to charge students just $5 to participate in its reuse system all year, without tracking return rates or worrying too much about lost inventory. “We don’t have a list of subscribers,” said Andrew Chaplin, the dining team’s general manager. The program “runs itself.”

Representatives from PR3 told Grist that plastic has been a hot topic of debate among consensus body members, and that the final version of the standards is likely to move away from the “plastic-free” recommendation. “The standards are going to address this with the understanding that if the world can move away from plastic, great, but in the meantime, before that’s feasible, we’d better move where we can,” said Amy Larkin, PR3’s co-founder and director, who pointed out that moving to reusable plastics will still make a huge dent in overall plastic demand. “Let’s get rid of 90 to 95 percent of the production of single-use packaging.”

Rather than calling for specific container shapes and sizes, PR3 has drafted a few broad requirements — like that containers be designed to “optimize durability,” and that they follow “best practices for recyclability.” They must comply with existing food-safety regulations. Optionally, companies may label products with a universal symbol — kind of like the ubiquitous “chasing arrows” used to indicate recyclability. Such a symbol doesn’t yet exist for reuse, but PR3 has proposed one: a black, white, or orange rose-like pictogram along with the word “reuse.”

More specific design elements are included only as recommendations. To make washing easier, for instance, PR3’s draft says reusable containers should have interior angles no smaller than 90 degrees, as well as “feet” to maximize airflow during drying. They also say containers should “nest” to save storage space and make transportation easier.

This flexible approach fits into a category that EMF calls “bespoke with shared standards,” where containers can vary from brand to brand while still sharing common characteristics — like where labels are placed, or the width of a bottle’s mouth. This leaves big brands free to design their own unique packaging if they want to.

PR3’s approach aims to appease big businesses by allowing them to keep using containers that look and feel very different, so long as they conform to a set of broad requirements. “Product companies want that kind of autonomy,” Juska told Grist.

Coca-Cola, for example, sets itself apart with its iconic — and patented — hourglass-shaped Coke bottle. And beauty companies are notorious for differentiated packaging: Walking down the perfume aisle, you might see bottles shaped like everything from a high-heeled shoe to a kitten.

Many reuse advocates want to do away with those unique container designs, going even further than what PR3 has suggested in order to enable sharing among different companies — a situation where packaging is considered “pooled” within a market. So instead of an extravagant diversity of perfume bottles, all fragrances might come in interchangeable cylindrical jars.

A small number of companies — especially in Europe — already do this. For example, through a German program called Mach Mehrweg Pool (roughly translated to “Make Reuse Pool”), brands share a collection of identical glass jars that can be filled with different foods. When consumers return the empty containers to a supermarket, a logistics provider picks them up and brings them back to food producers for cleaning. Another organization called the German Wells Cooperative runs a similar program for reusable soda and water bottles, counting more than 150 beverage makers as members.

Other companies that have experimented with pooling, however, have only done so within the brands they control. Coca-Cola, for instance, has a “universal bottle” initiative in South America in which a single, standardized reusable bottle can be used for all of its beverage brands — Fanta, Sprite, Coke, and others. But the initiative is not universal across company lines; you couldn’t refill a Coke bottle with Pepsi.

Tom Szaky, founder and CEO of Loop, a “global reuse platform” that is represented on the PR3 panel, said standard-setters shouldn’t try to resist companies’ impulses to differentiate. Brands should be allowed to experiment with both unique and standardized reusable packaging and then “let the market decide” which is preferable, he told Grist. He raised concerns that pooling might not make sense for some particular products — like baby food, since shared containers can increase the risk of contamination, and babies are more vulnerable to illness.

There is already evidence, however, that companies are leaving money on the table by choosing not to pool their containers. According to EMF’s direct comparison of pooled and nonpooled standardized packaging, pooling containers reduces the cost of reusable packaging systems by up to 28 percent.

Plus, at least some intervention — perhaps regulation or financial incentives — is likely required to create conditions that are more favorable to reusables; a hands-off, market-led approach is what has led to today’s proliferation of throwaway plastics. EMF’s modeling suggests that only reuse systems “built collaboratively from the outset” can reach cost parity with single-use. Exactly what that collaboration will look like, however, is unclear, since the kinds of government regulations that could help foster it might be incompatible with the United States’ free market ethos and antitrust laws. Internationally, some cities and countries have done more than the U.S. to promote reuse, but none has gone as far as what EMF is suggesting.

Plus, at least some intervention — perhaps regulation or financial incentives — is likely required to create conditions that are more favorable to reusables; a hands-off, market-led approach is what has led to today’s proliferation of throwaway plastics. EMF’s modeling suggests that only reuse systems “built collaboratively from the outset” can reach cost parity with single-use. Exactly what that collaboration will look like, however, is unclear, since the kinds of government regulations that could help foster it might be incompatible with the United States’ free market ethos and antitrust laws. Internationally, some cities and countries have done more than the U.S. to promote reuse, but none has gone as far as what EMF is suggesting.

Even in the absence of robust regulations, PR3’s standards are likely to nudge the country — and the world — in the right direction. Once they’re finalized, PR3 plans to submit them to the American National Standards Institute, the U.S. member organization of the ISO. From there, the standards would be opened up to public comment, potential revisions, and then final approval. PR3 would have to go through a separate submission and review process to get the standards approved by member countries of the ISO.

What would happen next is unclear. Other ISO standards — like for information security and energy efficiency — have been voluntarily adopted by individual companies or industry groups, either because they contain genuinely useful guidance on a complicated issue or because they increase businesses’ perceived trustworthiness.

ISO standards can also inform government regulations and international agreements. According to Juska, PR3 is already in talks with Canada’s environment ministry to shape new rules on reusable packaging, and the same thing could happen in any number of other jurisdictions. Juska is also hopeful that PR3’s standards will be acknowledged by or incorporated into the United Nations’ global treaty to end plastic pollution. The latest draft of the treaty mentions the need for standards — including for reusable packaging systems — some three dozen times, which Juska said is indicative of how “desperately needed” they are.

“If we want everyone to move in the same direction, we need to set some design parameters for how we want the system to function,” she said.

*Correction: This story originally misattributed Szaky’s comment about baby food to a different person.

This story was originally published by Grist with the headline What will it take to get companies to embrace reusable packaging? on May 1, 2024.

Last week, the EPA released a suite of long-awaited rules meant to cut down the carbon that the U.S. emits when generating electricity. The rules primarily target existing coal plants and new natural gas facilities, in many cases requiring dramatic emissions cuts that won’t be possible without an unprecedented deployment of carbon capture. (The new EPA proposals are part of an ongoing flurry of federal regulatory actions that must be issued by May 22 to minimize the possibility that they’ll be rolled back if Republican Donald Trump defeats President Joe Biden in November’s election.)

The EPA’s new power sector rules have been widely scrutinized for their potential impact on the country’s electric utilities, which have lately been drawing up plans to expand natural gas capacity in response to the growing electricity demand promised by new industrial facilities, AI-supporting data centers, and electric vehicle adoption. However, last week’s rules also contained substantial new controls on the pollution generated by the nation’s aging fleet of coal-fired power plants — as well as the toxins left behind by the many that have already shuttered — including a proposal that closes a longstanding loophole in federal regulations governing the cleanup of coal ash, a toxic waste byproduct of the coal-fired power process.

The new rule builds on a landmark 2015 rule prohibiting coal ash from being permanently stored in places where it comes into contact with groundwater. This was meant to reform the widespread practice of creating so-called coal ash ponds where the toxin is stored in a wet slurry. While at that time the EPA only applied the rule to coal plants in active use, the new rule will require the cleanup of hundreds of “legacy” coal ash ponds.

“EPA’s new rule is aimed at cleaning up coal plants once and for all,” said Lisa Evans, a senior attorney at Earthjustice, in a press briefing last week. “Coal plants will have to monitor each of these toxic dumps, stop the leaking of hazardous chemicals, and clean up groundwater when contamination is found. This is a watershed moment. For decades, utilities fought coal ash regulation every step of the way with legislation, lawsuits, and lobbying.”

Chris Bowers, an attorney at the Southern Environmental Law Center, noted that coal ash cleanup is an important environmental justice issue, in part because coal plants have been disproportionately located near poor communities and people of color; some 78 percent of all Black Americans live within 30 miles of a coal-fired power plant.

“Coal ash continues to be one of the largest, if not the largest, by-volume sources of industrial solid waste that is generated annually. Massive amounts are generated because we’re still burning coal for energy,” said Bowers.